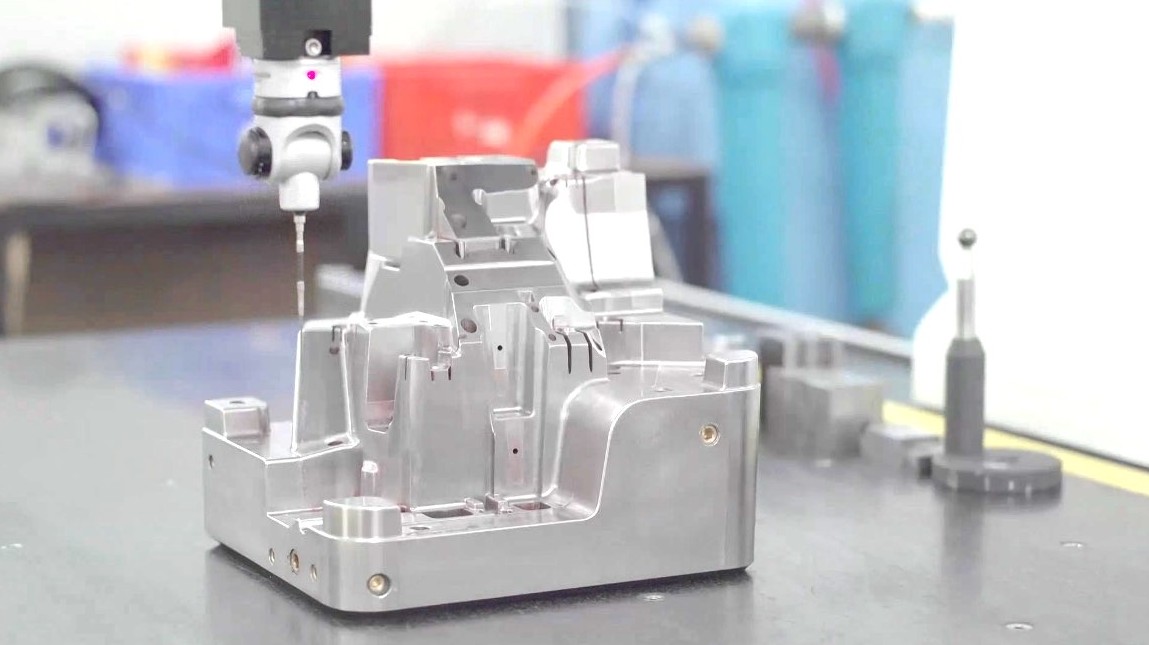

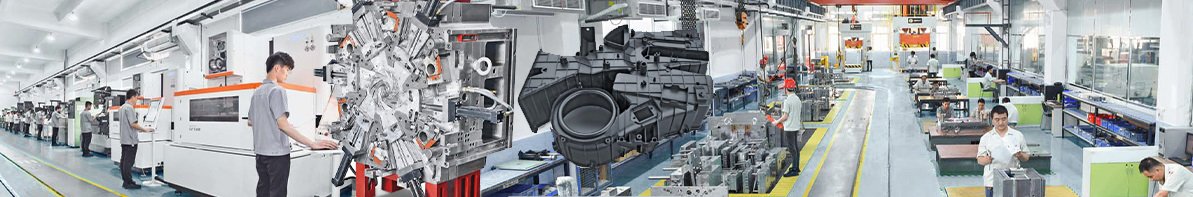

Quality Control

We are confident that our Quality Control team will ensure the quality of your project along with the newest equipment, which we are always updating, to cater to the demand of customers.In addition to sample approval, we apply strict verification process to ensure the mold is trouble-free at our customers’ facility, which includes :

① Mold Design Control

② Mold Steel Hardness Inspection

③ CMM Report for Mold Electrodes and Core and Cavity Steel Dimension Inspection

④ Mold Pre-Assembly Inspection

⑤ Cooling Line test to avoid Leakage

⑥ Report for Mold Trial and Samples Inspection

⑦ CPK Report before Mass Production

⑧ 4 hours None-Stop Production Prior to dispatch

⑨ Pre-Shipment Final Inspection

⑩ Export Product Package Inspection

Tolerance

Factors affecting the tolerance of injection molded parts include plastic properties, product design, mold design, injection molding process, etc. When we talk about injection molding product tolerances, it’s better to consider the appearance and function of the finished product and the cost.

Usually, MJX Mold takes DIN-16742 as our injection molding tolerance standard, and for the automotive industry, we comply with the QC-T-29017-1991 automotive industry tolerance standard as our standard. When the customer has special tolerance requirements, we strictly follow the requirements.

We are typically able to maintain a machining tolerance of +/- 0.003 in. (0.08mm) with an included resin tolerance that can be more than but not less than +/- 0.002 in. /in (0.002mm/mm).