Electronic

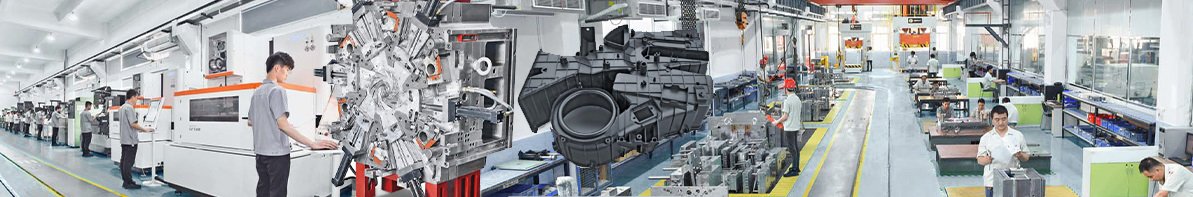

MJX Mold has been a trusted partner to the electronics industry for over 20 years using injection molding techniques to create complex shapes and geometries, whilst maintaining tight tolerances and high quality for electronic parts.

Injection molding plays a major part in electronic component manufacturing with the majority of electronic components utilizing plastics for their inert characteristics, flexible applications, conductive and non conductive properties, and low assembly costs.

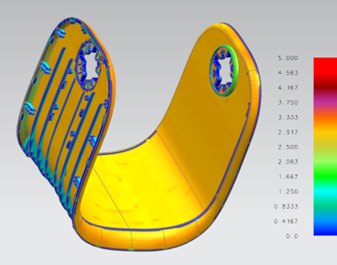

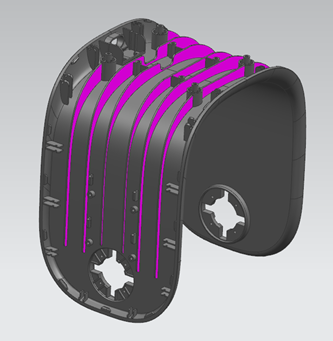

Successful Case Inner Bracket

|

|

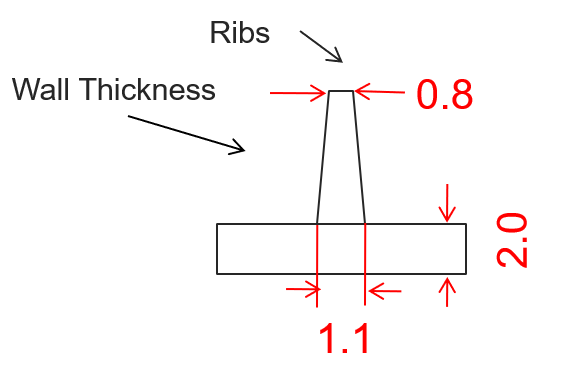

| Wall Thickness 2mm, ribs 1.2mm | Thick ribs might cause shrinkage marks |

Modification: | |

Project Name | HF3 Laser Projector Inner Bracket |

No. of Cavity | 1x1 (Reverse Mold) |

Steel | Groditz Stee for Core(718H) ; Cavity (S136) |

Injection System | Value Gate direct on the part |

Resin | 70% PC+30% ABS V0 |

Shrinkage Rate | 1.0055 (0.55%) |

Surface Finishing | Part: Off-White+Bead Blast |

Tooling Size & Weight | 450*600*650 mm; 3500KG |

Part Weight | 234g; 156*129*185mm |

Press Ton | 380 Ton |